End of Arm Tooling Design

The use of robotics in the industrial space has exploded. Long a staple of the automotive industry, robots are getting into all forms of industry.

SOLUTION

Robotics users are able to achieve faster ROI, putting robotics within reach of small to mid-size enterprises for the first time. Many are working alongside humans in the form of collaborative robots (cobots). The key to every successful robotic work system implementation is the robust and functional design of the end of arm tool (EOAT).

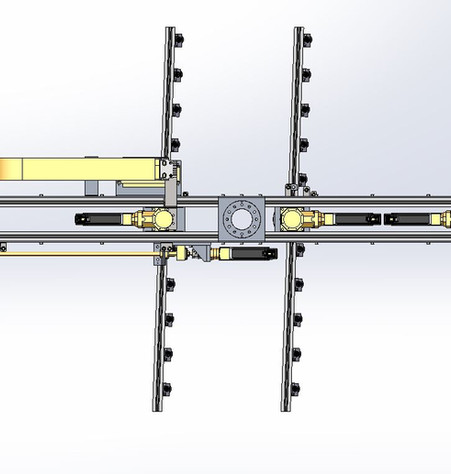

Flexibility is one of the biggest differentiators in EOAT equipment on the market today. Traditionally, one EOAT has been designed to complete one task thousands of times. It always grips the same object, picks it up , and places it on another belt or predetermined place. Specific gripper fingers are built for this task (pneumatic, electric, or vacuum) depending on force and requirements. But that is no longer sufficient for many of today’s applications. Manufacturers need EOATs that are able to perform multiple tasks, or that are easily interchangeable.

There are many different types of EOAT for robots: grippers, welding torches, force-torque sensors, material removal tools, collision sensors, tool changers , and more. The application dictates which type of EOAT is needed.

It is very important to choose the best EOAT for your system and your business in order to get the most versatility and functionality. The machine design engineers at Innovative Design Works can help concept and create the perfect end of arm tooling for your application. Just contact us today.